Standard Edge

Coil comes off slitting lines with a #3 slit edge, the standard in the industry. The #3 slit edge has a slight burr but is acceptable for most applications. The burr will generally alternate between the strips with one strip having the burr going up and the other with the burr going down. (For narrow cuts we can run the coils with all burr down or up by twisting the strip.) The #3 edge is as follows:

While we always aim to produce product with minimum burr, camber and wave, there may be applications that require stainless steel edging to produce a different edge or additional shape correction. If your processes or products demand a better edge, Scott Stainless Steel, Inc.’s stainless steel edging is for you.

Deburring

We can remove the burr normally associated with a slit coil. This edge is referred to as a deburred edge, a safety edge or a #5 edge. Deburring the edges will also improve shape characteristics producing a strip with less camber and less wave in addition to less burr. The #5 edge, deburred edge or safety edge is as follows:

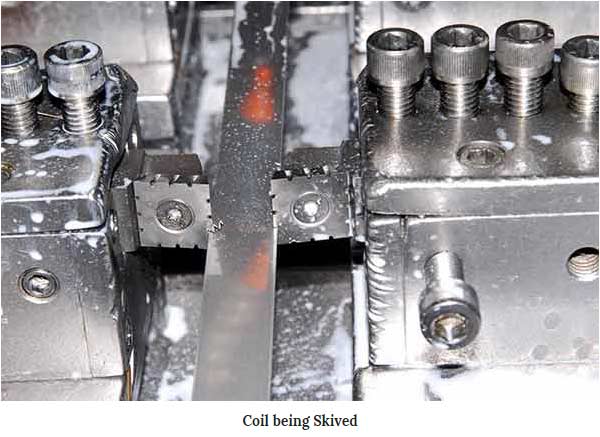

Skived Edges

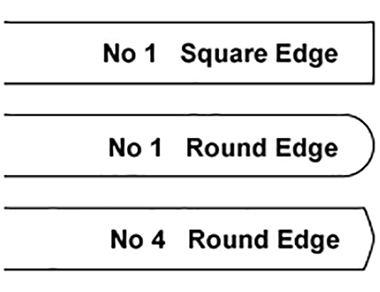

We can also provide skived edges, an edge produced by machining the strip. Skived edges can be #1 square, #1 round, #4 round or specialty edges such as Vee edges and Compound edges. We will work with you to supply the best edge for your production.

Some skived edges are as follows:

All edging processes will improve strip shape. A stainless steel strip that has been de-cambered and deburred or skived will be flatter and have less wave.

All coils run on the edgers can be supplied to you as traditional “pancake” coils or oscillate wound. Oscillate or traverse wound coils allow several smaller coils to be welded together and uniformly wound like kite string. This allows for larger coils. Larger coils mean fewer coil changes, longer runs, less scrap. . . all attributes that increase your profitability.